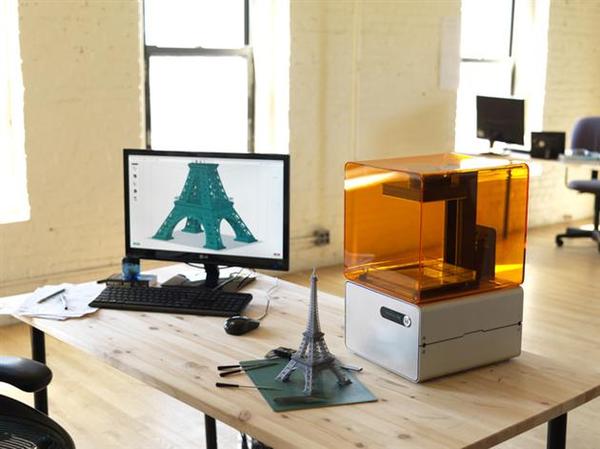

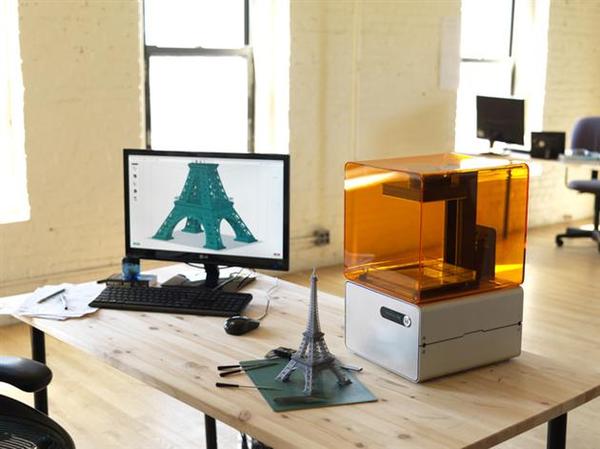

3D Printer for $3000

wetcircuit

Posts: 0

wetcircuit

Posts: 0

I'm not sure how this process differs from others, but a kickstarter campaign is bringing a desktop 3D printer to market for around $3000!

http://formlabs.com/

boingboing says starting price is $2300

http://boingboing.net/2012/09/26/form1-a-new-2300-high-resol.html

The volume is still small (about 5" x 5" x 6.5") but the process seems seems to allow for extremely high resolution objects and provides a method of support "pegs" that are easy to disconnect (like "pulling apart velcro")....

Formlabs-Desktop-3D-Printer-1.jpg

630 x 471 - 37K

Comments

Cool, thanks for the info!

Do you think they'll take payment in old comic books?

People are going to use those things to make guns.

Actual guns are much cheaper... :smirk:

I guess that would depend on the book...now wouldn't it?

I don't know anyone who would turn down something like a nice copy of Amazing Fantasy #15 or Batman #1...although you'd be able to buy a few more than 1 of those machines with either of those...of course a Superman #1, Detective Comics #27 or Action Comics #1 would get you just about anything you want...

So...

Actually, it's already been done (Google Reprap printed AR 15).

If you don't mind tinkering a bit and working with open source software, you can get a 3D printer based on the RipRap design (self replicating printer) for around $600 (http://printrbot.com/shop/), some very good quality kits can be found for around $500-600. A good place to see what is currently available is:

http://3dprinting.com/news/what-to-buy-personaldiy-3d-printers-up-to-3500/

Many of the 3D printers based on the RipRap design are capable of making some very nice and very detailed models. If your looking to making high res ultra detailed models, you probably want to go with one of the high end RipRap based printers with metal parts (many are less than $1,000). They really do work, my son got one of the kits and was printing models in less than 5 hours.

Edit - Just thought I'd add that I ran across the printed gun receiver while researching the RipRap printers, not something I would recommend anyone doing with their 3D printer!

For a gobsmacking look at what 3D printers can now do "out of the box", take a look at this:

http://www.youtube.com/watch?v=22q7MViXrq4

From about 39 minutes... :)

ETA: Euh - first time posting on the new forum. Yuck...

:gulp: OMG!!! Working parts and everything! WOW!

Manufacturers have been doing that for decades. Converting "computer aided designs" (CAD) to real stuff using "computer aided manufacturing". They use machines called CNC machines and other devices to convert 3D stuff to real stuff. It's how most detailed metal parts for automobiles and other machines are made.

Instead of spending all of that money on a 3D printer you can convert your Carrara object to a digital file, send it to a CNC company, and they'll "print" it out for you. But without the limitations that these 3D printing devices have (size, materials, etc.).

The only thing "new" about the concept is limiting it, by having to make it small and affordable and using only cheap plastic so you can use it at home.

But it seems real cool.

3D printing has an edge on CNC machining for small items. Jewelry is a good example.

You can get a 3d print made for far less than you can get something 5 axis machined. That makes it affordable for just about everyone.

If you want to develop something for casting or molding, the "pro" 3d printers produce a much higher surface quality than what is available in "home" models.

Holly's link is a good example of how far the technology has come in a relatively short period of time with something that is affordable and produces relatively high quality parts. I think we we will see versions of this in a few years that can produce parts with resolution like what you can get on a Polyjet now.

Absolutely. If you want cheap plastic jewelry, then sure, get a cheap 3D print. But personally I think the practical uses of 3D printers, using only that specific plastic, and limited in size, are extremely limited. Aside from being a cool, whizz bang thing, there aren't many people who are going to drop a few thousand $$ on a printer that only gives them a small, plastic replica.

And if you're going to produce stuff to sell, I suspect you're gonna want a higher volume solution, with different materials.

Yes, it's very impressive how they can produce detailed replicas, but I'm just not convinced that it's very practical for the average person.

Absolutely true. They are not selling to a "home" market. Their ads all imply a smallish design firm. Turtleneck sweater hipsters in a loft with overpriced skinny furniture... and it runs on osX! LOL

The leap here is not to your garage for a home hobbiest, the leap is from the "machine shop" to the office.... I know a ton of production people who build temporary pop-up structures for marketing and events. They are constantly needing to invent some small joint or connector or mounting bracket.... For a group like that, the ability to make prototypes in-house would allow them to evolve faster....

To quickly make mock-ups and such with out spending hours cutting out foam-core and sticking it together only to have to reassemble it at the last minute...yeah, that's worth $3K, if that's what I was doing for a living.

The 3d print can be used to make an investment casting for jewelry, using a suitable material that will burn out when fired. So the "print" is not the end result, but just an inexpensive way to produce a positive for casting.

I'm curious to see how this compares to makerbot.

It's amazing to see machines costing 2-3K producing the same, if not better, results as machines costing 100K a few years ago. It reminds me of the progress inkjet printing made in the 90s-early 2000s. I don't think we'll get 3D printers as cheap as inkjet, but I wouldn't be surprised to see a model under $1000 next year, which will allow hobbyists to afford one.

Yeah...but then again, who would have thought of a $100 laser printer?

Absolutely. If you want cheap plastic jewelry, then sure, get a cheap 3D print. But personally I think the practical uses of 3D printers, using only that specific plastic, and limited in size, are extremely limited. Aside from being a cool, whizz bang thing, there aren't many people who are going to drop a few thousand $$ on a printer that only gives them a small, plastic replica.

And if you're going to produce stuff to sell, I suspect you're gonna want a higher volume solution, with different materials.

Yes, it's very impressive how they can produce detailed replicas, but I'm just not convinced that it's very practical for the average person.

Its definitely for small volume. But you aren't limited to just plastic any longer. There are companies that will print in other materials including metals and ceramics.

There are also many forms that cannot be machined, but can be printed.

Very true. Bathsheba Grossman does some amazing sculptures that are 3d printed and cast, and could never be machined.

I like these too-

http://www.michael-hansmeyer.com/projects/columns.html?screenSize=1&color=0#1

Tongue-in-cheek review of a London 3D Printer fair... Poser is mentioned in the video...

http://crave.cnet.co.uk/gadgets/3d-printed-marvels-blow-your-mind-in-futuristic-photo-gallery-50009607/

One of the more interesting things is the cat mummy...

Under <$1K has been here for awhile, check out the $499 Solidoodle printer. I saw the $1200 Cubify Cube printer demo'ed at Siggraph LA. It was pretty fast. Unless you plan to make things and sell them for profit, its probably cheaper to use a 3D printing service bureau like Shapeways. There are cheap 3D CAD programs like ViaCAD to convert Carrara file exports to STL files. I think printing bureaus accept more file formats making the process less painful. No I haven't done this yet, just researched it.</p>

You can upload OBJ format to Shapeways.

They have Hexagon listed as a compatible application, but the OBJ from Carrara is the same thing, and it works.

In the past 8 month I've been working with a client to design a range of kitchen-ware items , and we used Shapeways to prototype and refine the models. which was fast, and cost effective.

I can't fault shapeways for their quality and fast turn around time for rapid prototyping, and they have all the equipment and experienced staff to do it for you. It just makes life easier and really helps the design process. but the current range of materials and colour options available can be limiting.

Although,.. they can currently print in Metal (stainless steel, silver, gold etc..) or Ceramics, and Glass. as well as plastics.

Long term, with better material variations, 3D printing could bring a real global change in commercial product distribution and retail.

imagine downloading and printing a new pair of shoes using the shredded material from the old ones.

Right now it's expensive, like all new technologies, an the available materials are not always the best materials.. compare the initial price of CD "players" (1k+) when they were launched, to what they are now

I also like the HP 3D printers, which are using ABS plastic. but they're way too pricey to be a "Home" 3D printer right now.

3D printing has been around for at least 25 years, btw. Originally called Stereolithography, or Rapid Prototyping, engineers have been getting parts like this for a long time. It's only the branding (ie 3D Printing) and the target audience (general consumer) that's changed in the last few years. But they've been promising us a machine for under 5k for more than years now, and even 2 years ago I heard that they'd have one in the desktop price range (350-500 dollars) any day now.

It's getting much closer, but still hasn't happened.

Yeah, but I'm waiting for the unit that directly converts energy to matter...

There is a huge difference between CNC and 3D printers. 3D printers are additive, whereas CNC machines are subtractive. This makes them more versatile and cost effective right off the bat. The more expensive commercial models can mix lots of different materials and even work with metals (good luck really making a gun with a consumer model, or at least one that won't disintegrate after a few rounds are fired through it).

A lot of people think this is the next big revolution - the same freedoms and open access the Internet has brought to some many areas are now extended into the last frontier - manufacturing of physical goods. Now just about anyone can conceive of a product and either build it themselves with a consumer/semi-commercial printer, or farm it out to have built. Especially here in the US, lots of idle manufacturing capacity (you know, from that "loud sucking sound") is being converted to use as ad-hoc, low volume manufacturing facilities that anyone can send a CAD file to and have their product manufactured. This breaks down a barrier that has existed for 150 years, i.e. the entire Industrial Revolution, during which a small elite controlled all the means of production. Those barriers are now quickly falling, and will be gone probably in a matter of years.

This is more good news for creative professionals, BTW. More and more, people with strong design skills are in great demand. Now you can use your skills for more than just designing websites or for media-related work. Now you can use your modeling skills to design real physical products. Lots of people will have ideas for products to be built, and now have a means to manufacture them, but don't have the creative or technical skills to pull it off, so they will be looking for people who do. I just dabble in modeling (my "real" job is as a programmer), but for those of you who are semi or seriously involved in it as a career, these are skills you might want to acquire very soon.

BTW, there's a good book on all this that just came out called "Makers: The New Industrial Revolution", it's worth checking out if you're interested in this stuff.

There is a website called kickstarter that allows makers to make a pledge to startup companies in return for their products. There are a few makers of 3d printers at this site. The largest one at this particular site will print 12" x 12" x 12" and can be had for a $1275 pledge.

http://www.kickstarter.com/projects/vision3dprinter/the-vision-not-just-a-3d-printer-a-dream?ref=card

Aside from some kind of StarTrek tech, 3d printing will never put CNC out of work in the foreseeable future. Natural materials like wood or stone will never be 3d printable in the current sense. That's not to say you might not eventually get a suitable proxy material (there are currently castable or machineable alternatives to stone and wood), but if you want a REAL hardwood piece of furniture for example, CNC or traditional woodshop equipment is going to be the only way to do it for many years to come.

As far as opening up opportunities for designers, I think it can, but designers are impacted by the global market when it comes to providing services. If anything, new tech forces them to acquire new tools and skills to remain competitive. Not that there is anything wrong with that, as that is the nature of change.

Its a pity that more business owners can't adapt to changes in tech the way designers must.

I recently had a business owner tell me he wanted to improve his method for documenting how his equipment was manufactured. He complained that it was taking to long to do it using his current methods. I recommended several changes or updates that would not have caused the company any significant investment. Sort of a no brainer, right?

Wrong, because he could not understand it, he was unwilling to change the process, a process which he had already stated he was unhappy with. And the guy's a freakin engineer. Go figure. Sorry for venting. I have seen this so many times in my working career that it is truly scary.

Sorry, but that's just silly.

Anyone with a hammer and saw can manufacture products from wood. Anyone with simple metalworking tools, or with access to small automated machining tools (lathe, CNC, etc., stuff you can buy at Home Depot) can manufacture metal products. Anyone with a hammer and chisel can manufacture stone products. And anyone with a brain, but lacking the tools necessary to produce large quantities, can hire a company to manufacture it for them. What do you think Toyota does, or Apple does, or most other companies do? They design stuff, and have manufacturing firms make it for them. And you can do the same thing. Today.

I think the problem is that there are a lot of people who don't really understand manufacturing, and what it takes, and think it's some kind of magic that the average person has no access to. That's just not right. Not even close.

"Small elite"? Gimme a break. Those barriers don't exist. But it's more fun and exciting to imagine a world where you can build a new car using your computer and a "desktop printer", so people like to believe it's the next new thing.

And to say that "additive" is automatically better than "subtractive" is just nonsense. If there's some way to "additively" generate the equivalent of the various metals that are used in the majority of industrial equipment by using a desktop printer, then you might have something. But only if it does it cheaper and better and faster than existing subtractive processes.

But I know that anyone who doesn't think that "anything new is awesome" is just an old dinosaur, so I'll just be content as an old dinosaur. But come back to me in 20 years and let me know how your 3D desktop printer has changed the world....

I think if you actually evaluated what would be required in terms of costs and resources to do that, it would end up being far more expensive and inefficient, compared to paying some guy in China $3 US per day to cut and sew the shoes by hand. And I think it's probably real tough, if not impossible, to additively generate a leather-like material from scraps.

I'd really be interested in hearing of an actual example where this technology would make a real difference. Just ONE product that would be indicative of this "global change". And by example I mean one that has been really evaluated for costs and practicality.

But it's fun to imagine, I suppose.